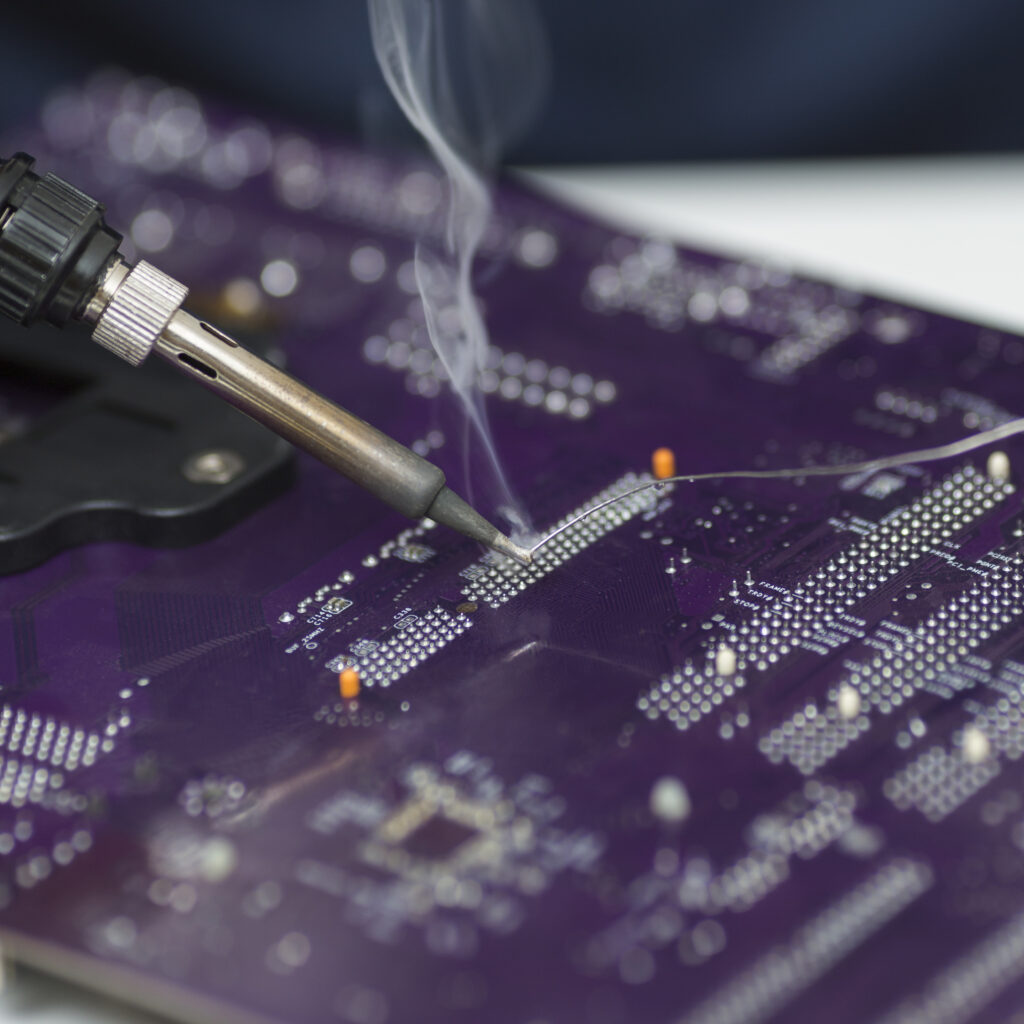

PCB manual drill

A PCB manual drill is a hand-operated tool for creating holes in printed circuit boards, used for placing components. These drills are typically spiral push types that operate by pressing the body downward, allowing for precise, vibration-free drilling suitable for DIY projects and home use. They generally accept drill bits in a 0–3mm range.

A PCB manual drill is a hand-operated tool used to create precise holes in printed circuit boards for mounting electronic components such as resistors, capacitors, and ICs. It is commonly used in DIY electronics, prototyping, repair work, and small-scale PCB fabrication, where high accuracy is required but advanced machinery is not necessary.

Unlike electric drills, manual PCB drills use a spiral push mechanism—you simply press the body downward, causing the bit to rotate and drill through the board. This design allows for slow, controlled drilling, minimizing the risk of cracking the PCB or misaligning component holes. The lightweight and compact design also make it ideal for hobbyists and electronics enthusiasts working at home.

Key features

Mechanism

It is a spiral push drill where downward pressure on the body rotates the bit to drill the hole.

Drilling range

The typical drilling capacity is between 0mm and 3mm, which is ideal for most through-hole components.

Precision

Being non-electric and manual, it offers greater control and is less likely to cause damage from excessive speed or vibration, making it great for delicate work.

Applications

Primarily used for drilling component holes in home-made PCBs, it is also suitable for other crafts like jewelry making or working with other soft materials.

Ease of use

The simple downward push action makes it easy to operate for both beginners and experienced hobbyists.